DESIGN OF AUTOMATED SUPERVISORY CONTROL & ADVANCED PROCESS CONTROL BASED ON MACHINE VISION, SENSOR AND PROCESS DATA FUSION FOR REAL TIME PRODUCTION PARAMETERS TUNING

Standard machine vision applications are used to check quality or presence and generate an alarm or send a signal to an actuator when a problem is detected.

Changes to the process parameters to avoid bad quality or defects are usually done offline, manually. This leads to long periods of sub-optimal production quality. The detection of problems occurs only after they cross the threshold set into the computer system.

Changes to the process parameters to avoid bad quality or defects are usually done offline, manually. This leads to long periods of sub-optimal production quality. The detection of problems occurs only after they cross the threshold set into the computer system.

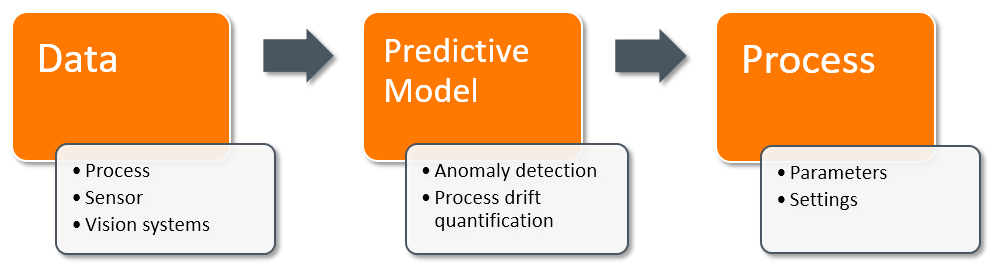

Thanks to the combination of our competences in computer vision, machine learning and industrial Advanced Process Control, we can go one step further: Derive process parameters from measurements made on industrial camera images, but also integrate other sensor and process data.

Predictive models and artificial intelligence algorithms first detect anomalies, process drift in-line in pictures and sensor data. The smart software then compensates the right process parameters before the problems even occur.

The result is automated tuning of process parameters - supervisory control - in real time to optimize product quality and avoid problems and defects as much as possible.

It also improves operational efficiency and productivity and reduces downtime.

Predictive models and artificial intelligence algorithms first detect anomalies, process drift in-line in pictures and sensor data. The smart software then compensates the right process parameters before the problems even occur.

The result is automated tuning of process parameters - supervisory control - in real time to optimize product quality and avoid problems and defects as much as possible.

It also improves operational efficiency and productivity and reduces downtime.

Interested? |

| ||||||

Are you interested to find out what we can do to ? Contact us to find out: call us at +32 486 31 68 09 during office hours CET, or send us an email: